Do not compromise on the engine's emissions performance.

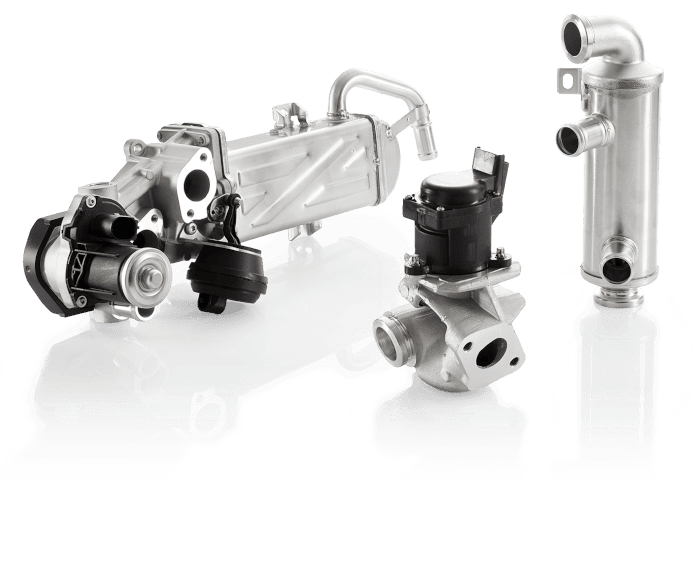

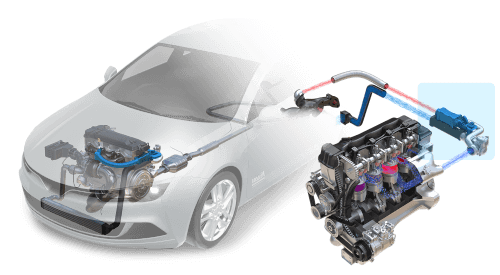

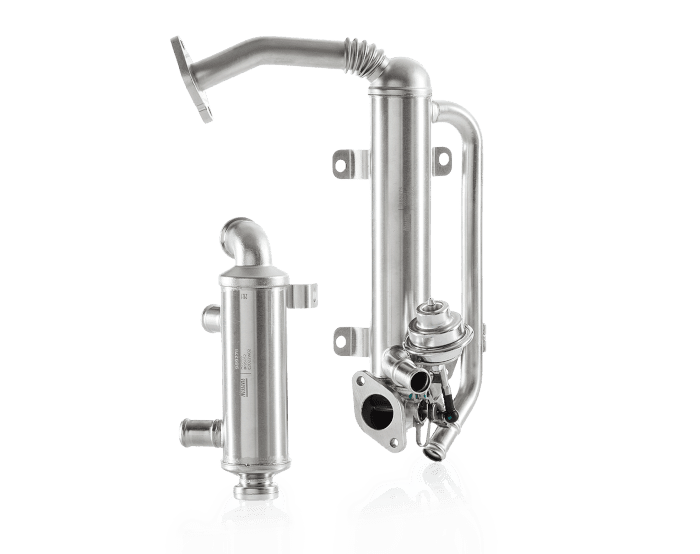

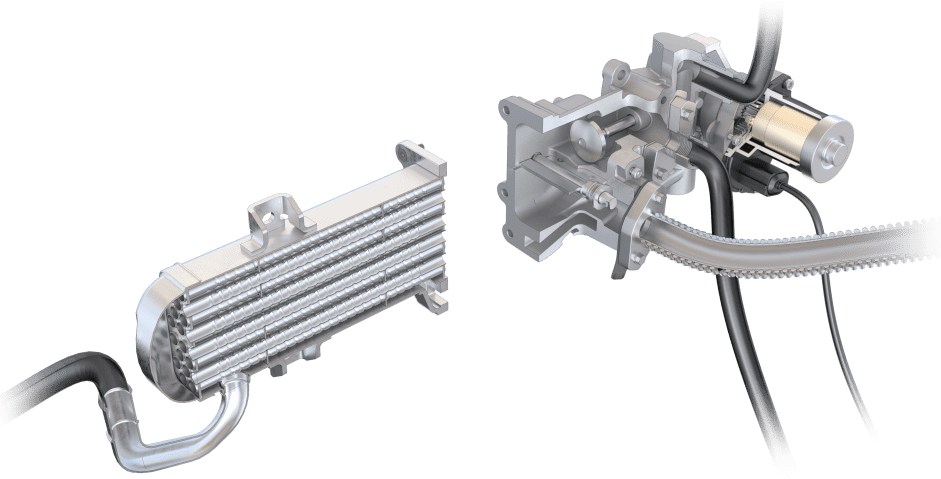

Choose premium aftermarket EGR spare parts. Our complete solution consists of EGR valves, modules, and coolers of the Genuine Nissens Quality standard.

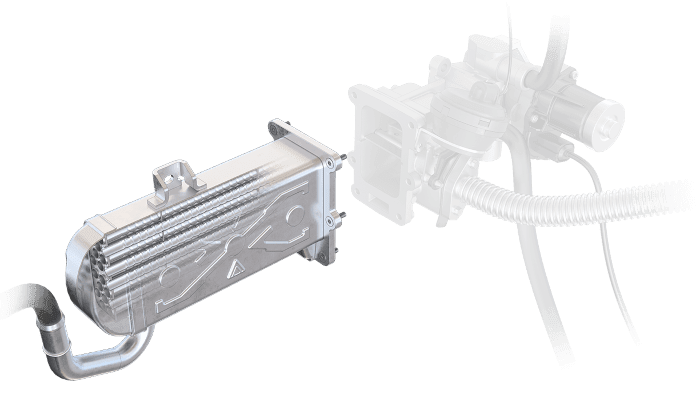

In our components, we apply only the industry's highest-rated materials. We thoroughly test their critical functions, calibration, and fit and provide design and material improvements, which contribute to the part's supreme thermal performance and durability.

EXPERIENCE

EXPLORE